All products

GH-120CE

GH-120-WE-L

P-GH-90

All products

GH-120CE

GH-120-WE-L

P-GH-90

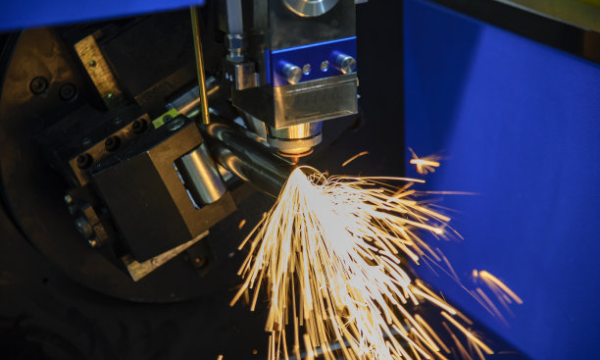

Laser cutting and other methods

Understand how laser cutting outperforms other cutting techniques in terms of precision, maintenance, and consumable usage.

Mechanical cutting and laser cutting

Unlike mechanical cutting (which involves sawing, shearing, milling, or similar electric tools with significant errors), laser cutting is a non-contact, CNC machining process. Among these two methods, laser cutting has higher accuracy and clearer edges. Laser cutting significantly reduces material waste, rework, and subsequent surface treatment.

Water jet cutting and laser cutting

Although both waterjet cutting machines and laser cutting machines require a significant initial investment, the former requires a substantial amount of ongoing operation and maintenance costs. In addition to the abrasive cost of water jet cutting, the operation also includes maintenance of the high-pressure system, repair of leaks or wear, and subsequent cleaning. In contrast, laser cutting stands out due to its fast maintenance and low consumable usage.

Plasma cutting and laser cutting

Among these two methods, laser cutting generates a smaller heat affected zone, resulting in less material deformation and damage. Plasma cutting is considered an economical method; However, plasma pulses are not as precise as laser beams and may not be suitable for cutting thin or complex materials. In contrast, laser cutting has a wider range of applications and is safer, suitable for various materials and applications. In addition, plasma cutting requires regular replacement of cutting torch consumables and replenishment of gas.

In the dynamic world of product manufacturing, the pursuit of excellence depends on two key factors: carefully selecting raw materials and adopting advanced processing technologies. With the development of the industry, manufacturers are increasingly inclined towards innovative solutions that not only meet but also exceed the strict standards required for outdoor products. Standing at the forefront of this technological revolution is laser cutting, which has changed the way products are processed.

Laser cutting has significant advantages over traditional methods due to its unparalleled precision and efficiency. It can produce complex and clean cuts without wear and tear, which is very suitable for the high-quality requirements of outdoor products. This cutting-edge technology also allows for incredible design diversity, enabling the creation of complex patterns and shapes with impeccable precision. In addition, laser cutting improves manufacturing efficiency, reduces material waste, and shortens production time. By integrating laser cutting into their manufacturing process, manufacturers in the outdoor goods industry can achieve a level of detail and quality that sets their products apart.

The advantages of laser cutting

Laser cutting technology provides significant features and advantages in applications based on different product fields.

High precision: Laser cutting provides extremely high precision, which is crucial for outdoor products with complex patterns and intricate details.

Edge sealing: When cutting synthetic materials, the thermal effect of laser cutting can seal the edges and prevent fabric edge wear.

Non contact machining: Laser cutting is a non-contact method that avoids material deformation or damage that may occur during the physical cutting process.

Speed and efficiency: Laser cutting is fast, greatly improving productionefficiency, especially for large-scale production.

Reduce material waste: High precision and optimized cutting paths can minimize material waste to the greatest extent possible.

Multifunctionality: In addition to cutting, some laser machines can also perform carving, drilling, and other processes, providing more design and functional options.

Flexibility: Laser cutting equipment is usually computer-controlled and can easily adjust the cutting path to adapt to different designs and templates, which is particularly advantageous for small batch or customized production.